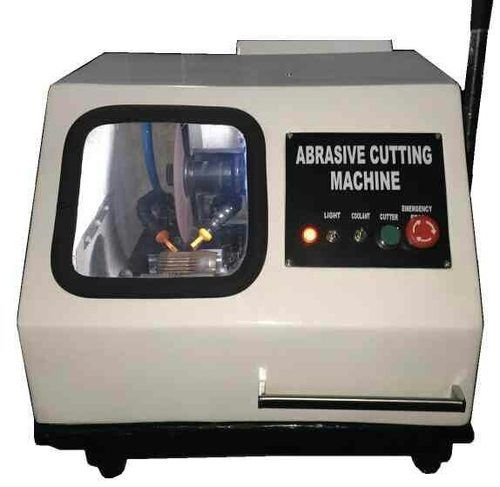

Metallurgical Cutting Machine Table Top

68000 INR/Piece

Product Details:

- Port Size 3/8 inch Inlet

- Operating Voltage 220 VAC

- Automation Grade Manual

- Temperature 0C to 40C

- Max Height 130 mm clearance under wheel

- Features Rust proof body, fiber reinforced cutting wheel, coolant system

- Response Time Instantaneous

- Click to view more

X

Metallurgical Cutting Machine Table Top Price And Quantity

- 1 Piece

- 68000 INR/Piece

- 600 mm x 400 mm x 400 mm

- Re-circulating

- Powder coated steel

- 1 HP (0.75 kW)

- Transparent shield, Interlocking switch

- Approx. 200 mm diameter

- <70 dB

- ISO/CE Certified

Metallurgical Cutting Machine Table Top Product Specifications

- Standard: 25 mm

- 50 Hz

- 1 per operation

- Approx. 55 kg

- Table Top

- Analog/Scale

- Manual

- Laboratory, Industrial use

- <80% RH

- Suitable for 10 mm 50 mm specimens

- Variable, up to 3600 rpm

- 0.1 mm

- Manual switch controls

- Cut position 0.2 mm

- Maximum 50 mm diameter

- Cutting metallurgical specimens

- 220V, 50Hz, Single Phase

- Instantaneous

- Up to 120 mm

- Metallurgical Cutting Machine Table Top

- Up to 50 mm solid or tube

- Rust proof body, fiber reinforced cutting wheel, coolant system

- 130 mm clearance under wheel

- 220 VAC

- 3/8 inch Inlet

- 0C to 40C

- Manual

- 600 mm x 400 mm x 400 mm

- Re-circulating

- Powder coated steel

- 1 HP (0.75 kW)

- Transparent shield, Interlocking switch

- Approx. 200 mm diameter

- <70 dB

- ISO/CE Certified

Metallurgical Cutting Machine Table Top Trade Information

- Cheque

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- All India

Product Description

Abrasive Cutter Is Rugged, Sturdy And Designed To Cut Metallurgical Samples To Optimal Quality Consistently And Safely. Cutting Wheel Mounted On The Spindle To Get The Optimum Output Of the Motor.

The Movement Of Cutting Wheel Towards The Specimen Is Applied By Handle fixed With Motor Base Pivot spindle And The Cutter Unit Is Balanced By Springs For Smooth Downward.

Features

- Table Top model cutter for sectioning metals ceramic and mineral

- Cutting capacity up to 50mm

- Spindle speed 1400rpm and cut-off wheel dia 8" (Max.)

- Cutting motor 2 HP

- Electrical Power Supply 3 Phase, 440 Volts

- Self centering Vice with 360 rotation jaw opening 2"

- Splash proof, corrosion resistant with see through hood

- Cooling by two high flow water jets to provide optimum cooling

- Coolant Tank for Capacity 20 Liter

Precision Cutting for Metallurgical Samples

Engineered for robust performance, this machine is ideal for preparing metallurgical specimens, supporting test speeds up to 3600 rpm with instant response time. Its 0.1 mm resolution and 0.2 mm accuracy enable precise sectioning, crucial for quality sample analysis in laboratories and research institutes. The analog scale display provides visual clarity for operators during every cut.

Reliable Safety and Durability

Safety is prioritized with a transparent shield and an interlocking switch that prevents accidental operation. The powder-coated steel body resists rust, while the fiber-reinforced cutting wheel enhances longevity. The re-circulating coolant system minimizes heat build-up, extending tool life and maintaining cutting quality even during prolonged operations.

Manual Control with Versatile Applications

Manual switch controls ensure straightforward operation, suited for varied test requirements. Capable of handling solid and tube specimens up to 50 mm diameter, the machine accommodates both laboratory analysis and industrial use. Its compact table-top mounting maximizes workspace efficiency, making it a sought-after choice for dealers, distributors, exporters, and end users across India.

FAQ's of Metallurgical Cutting Machine Table Top:

Q: How does the Metallurgical Cutting Machine ensure precise and clean cuts?

A: The machine uses a fiber-reinforced cutting wheel with a test speed of up to 3600 rpm, a re-circulating coolant system to reduce overheating, and an analog scale display to ensure cut position accuracy within 0.2 mm for clean and precise specimen cutting.Q: What types and sizes of specimens can this machine accommodate?

A: It supports cutting of both solid and tube specimens with diameters ranging from 10 mm to 50 mm, and a maximum test width of 120 mm, accommodating most standard metallurgical samples for laboratory and industrial analysis.Q: When is it necessary to use the coolant system during operation?

A: The coolant system should always be used during cutting, especially with larger or heat-sensitive samples, to efficiently manage temperature, protect the cutting wheel, and prevent damage to specimens.Q: Where should the Metallurgical Cutting Machine be installed for optimal performance?

A: Install the machine on a stable, vibration-free laboratory or workshop table with adequate ventilation, within ambient temperatures of 0C to 40C and humidity below 80% RH, to maintain safety and accuracy.Q: What are the benefits of the machine's safety features during specimen cutting?

A: The transparent shield provides visual monitoring while protecting the user from debris, and the interlocking switch ensures the machine operates only when the shield is engaged, significantly reducing the risk of accidents.Q: How can users control the machine and adjust cutting speeds?

A: Operators can manually control the unit via analog switch controls, adjusting the speed according to specimen hardness or thickness within a range of up to 3600 rpm for optimal cutting results.Q: What compliance standards does this cutting machine meet?

A: This machine is ISO and CE certified, meeting international safety, performance, and quality standards essential for reputable laboratory, industrial, or commercial environments in India.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email