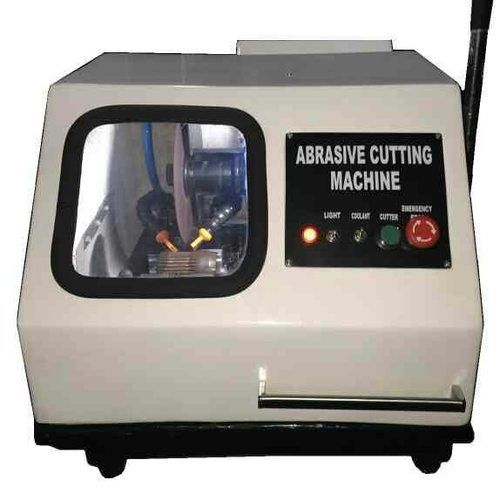

Abrasive Cutting Machine

Product Details:

- Port Size 1/2 BSP

- Power Supply 220V AC, 50 Hz

- Equipment Type Abrasive Cutting Machine

- Test Range Up to 100 mm cross-section

- Response Time Instantaneous (Mechanical)

- Humidity Up to 85% RH

- Max Height 400 mm

- Click to view more

Abrasive Cutting Machine Price And Quantity

- 1 Piece

- 75000 INR/Piece

Abrasive Cutting Machine Product Specifications

- 125 mm

- 400 mm

- Cutting Wheel up to 64 HRC

- Abrasive Cutting Machine

- Up to 100 mm cross-section

- Instantaneous (Mechanical)

- Up to 85% RH

- Laboratory, Industrial Workshop

- 2800 RPM

- 1/2 BSP

- 220V AC, 50 Hz

- 115 Kg

- 50 Hz

- 220V

- Manual Switch

- Analog

- Manual

- 5C to 45C

- High Cutting Precision

- 4 or 100 mm cutting capacity

- Single Specimen per Operation

- Manual

- Sturdy built, corrosion resistant, easy wheel change, protective cover

- Up to 100 mm diameter

- 300 mm

- Bench Top

- Metallurgical Specimen Preparation, Cutting of Hard Materials

Abrasive Cutting Machine Trade Information

- Cheque

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa, Asia

- All India

Product Description

Abrasive cutter is rugged, sturdy and designed to cut Metallurgical Samples to optimal quality consistently and safely . Cutting Wheel spindle is connected with motor shaft by pulley and belt mechanism. The movement of cutting wheel towards the specimen is applied by handle fixed with motor base pivot spindle and the cutter unit is balanced by springs for smooth chop type movement. Corrosion resistant window. Cooling by two high flow water jets to provide optimum cooling. Large (25mm) drain, re-circulation coolant tank with 30LTR. Capacity Working on 440 volts, AC main supply with coolant tank of sufficient capacity. The chop type cut off wheel machine is suitable for quick and clean cutting of metallography specimen from rods & tubes etc.

Features-

X-Y Movement Vice is made up of M.S, Specially designed.

Coolant circulation System is provided with suitable filtering arrangement.

Light attachments system is provided for clean and accurate cutting of samples.

Heavy Duty motor is provided 3 H.P , 3 Phase.

Large Viewing window to monitor the cutting operation.

Technical Data-

Operation -Manually by moving motor to cut the sample.

Cutting Operation :- By manual cutt-off wheel in chop type procedure.

Cutting Motor Power :- 3H.P,3 Phase.

Coolant Motor Power :- Tullu Pump.

Cutt-Off Wheel Speed :- 1400 RPM.

Dimensions :- 600mm W x 750mm D x 1000mm H. (Approx.).

Cutting Capacity :- 10-60mm.

Precision Cutting Built for Reliability

This bench-top abrasive cutter is engineered with a heavy-duty mild steel frame, supporting high-precision operations and a maximum specimen size of 100 mm diameter. Its sturdy construction and analog display make it an ideal choice for consistent and accurate results in laboratory and workshop settings.

Advanced Safety and Cooling Mechanisms

Safety is paramount, with a reliable safety interlock feature and a locking vise for secure specimen clamping. The integrated coolant system with a circulating pump minimizes thermal distortion, ensuring your samples remain undamaged, while the protective cover enhances operator safety.

Robust Performance and Simple Operation

With a powerful 3 HP motor and instant mechanical response, the cutting machine attains test speeds up to 2800 RPM. It supports a test width of 125 mm and a stroke of 300 mm, efficiently handling hard materials up to 64 HRC. Manual operation grants full control for precise results every time.

FAQ's of Abrasive Cutting Machine:

Q: How does the abrasive cutting machine handle hard materials?

A: The machine is equipped with an aluminum oxide cutting wheel, capable of managing materials up to 64 HRC hardness. Its robust build and integrated coolant system ensure smooth cutting with minimal thermal impact.Q: What is the maximum specimen size that can be cut?

A: You can cut specimens up to 100 mm in diameter and cross-section with this machine. The secure vise ensures the workpiece remains stable throughout the cutting process.Q: Where is this cutting machine best utilized?

A: This abrasive cutting machine is designed for metallurgical laboratories and industrial workshops where high-precision and controlled specimen preparation is required.Q: When should the cutting wheel be replaced?

A: Replace the cutting wheel when you notice reduced cutting efficiency or visible wear. The machine's easy wheel change feature makes maintenance straightforward and fast.Q: What benefit does the integrated coolant system provide?

A: The coolant system with a circulating pump keeps the blade and workpiece cool, preventing sample warping and enhancing cutting accuracy during prolonged use.Q: How is operator safety ensured during cutting?

A: Safety is managed through a protective cover, a safety interlock, and a locking vise mechanism, significantly reducing the risk of accidents or improper operation.Q: What is the process for operating the abrasive cutting machine?

A: To operate, secure your specimen in the vise, switch on the power, and manually guide the blade using the control switch. The system instantly responds, providing clean cuts with minimal noise (<80 dB).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+