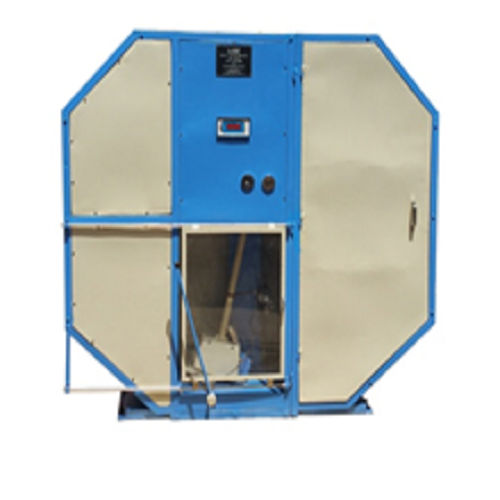

Digital Asi Impact Tester

50000.00 - 100000.00 INR/Piece

Product Details:

- Mounting Type Bench-top

- Port Size Standard sample port, 16 mm

- Max Height Approx. 350 mm sample to base

- Hardness Hardened impact striking edge

- Features Microprocessor-based control, automatic reset, high-precision sensor, easy sample placement, user-settable parameters

- Humidity 30%-85% RH

- Specimen Size Standard: 63 x 12.7 x 4 mm

- Click to view more

X

Digital Asi Impact Tester Price And Quantity

- 1 Piece

- 50000.00 - 100000.00 INR/Piece

Digital Asi Impact Tester Product Specifications

- Up to 300 mm

- 220V AC, 50Hz

- Material impact resistance testing

- 0.01 Joule

- Bench-top

- Standard sample port, 16 mm

- Hardened impact striking edge

- Approx. 350 mm sample to base

- Microprocessor-based control, automatic reset, high-precision sensor, easy sample placement, user-settable parameters

- Approximately 85 kg

- Digital automatic control

- 50J maximum impact energy

- Standard: 63 x 12.7 x 4 mm

- 30%-85% RH

- 1 50 Joule

- 0.5-0.7 MPa

- 220V AC

- Automatic

- 10C to 40C

- 50 Hz

- USB, RS232

- 0.1 Joule

- Digital Impact Tester

- 1 per test cycle

- <1 second

- Determination of impact strength of metallic and non-metallic materials

- Up to 40 mm

- Adjustable, up to 3.5 m/s

- 1J 50J

- Digital LCD

Digital Asi Impact Tester Trade Information

- 100 Piece Per Week

- 5-7 Days

Product Description

Our rich industrial experience supports us in offering Digital Asi Impact Tester. The offered tester is demanded for impact testing of concrete. We offer this Digital Asi Impact Tester in variegated specifications to suit various needs of our customers. The offered Digital Asi Impact Tester easily determines the amount of energy absorbed by a material during fracture.

Advanced Digital Control and Data Management

Equipped with microprocessor-based technology, the Digital Asi Impact Tester offers automatic control, adjustable test parameters, and high-precision sensors. Its memory function lets users store up to 1000 test records, allowing for easy recall and data management. Data can be exported via USB or RS232, or printed directly for comprehensive reporting.

Reliable Performance and Safety

The tester's robust mild steel construction is powder-coated for durability and ideal for laboratory use. Essential safety mechanisms, including an interlocked shield cover and emergency stop button, protect users during high-energy tests. The machine is supplied fully calibrated and supports user-settable operational parameters, ensuring reliable and repeatable measurements.

Versatile Application and Easy Operation

Designed for material impact resistance testing, the Digital Asi Impact Tester accommodates standard specimens up to 63 x 12.7 x 4 mm and up to a 50J impact energy range. Simple bench-top mounting and quick sample placement streamline the testing process, making it well-suited for research, quality control, and industrial applications.

FAQ's of Digital Asi Impact Tester:

Q: How do I operate the Digital Asi Impact Tester for impact strength measurement?

A: To operate the tester, prepare a standard specimen (63 x 12.7 x 4 mm) and place it securely in the sample port. Use the digital LCD interface to set test parameters such as test speed (up to 3.5 m/s) and impact energy range. Initiate the test using automatic digital controls and monitor results instantly on the display.Q: What are the benefits of using the Digital Asi Impact Tester in material testing?

A: This equipment enables highly accurate impact resistance measurements (with 0.1 Joule accuracy and 0.01 Joule resolution) in metals and non-metals. Its digital controls, automatic reset, and memory for 1000 results simplify testing workflows, ensure reliable data storage, and enhance reporting capabilities for laboratories and quality assurance teams.Q: When should calibration be performed and how is it verified?

A: Each unit is supplied with a calibration certificate and is factory calibrated for accuracy. For optimum results, regular calibration is advised according to your laboratory's quality protocol or after significant use. Verification involves comparing the tester's readings with certified reference standards, ensuring ongoing measurement precision.Q: Where is this impact testing equipment best installed and used?

A: The Digital Asi Impact Tester is designed for indoor laboratory settings, preferably dust-free environments. It should be placed on a stable bench-top to accommodate its approximate 85 kg weight, ensuring safety and optimal operation for research, testing, and quality control purposes.Q: What is the typical process for storing and exporting test results?

A: Upon completion of a test, results are automatically saved in the machine's internal memory, capable of holding up to 1000 records. Users can export data directly to a USB drive or via RS232 connection, or print records for further analysis and documentation, facilitating efficient record keeping.Q: How does the safety system on the Digital Asi Impact Tester function?

A: The tester is fitted with an interlocked shield cover that prevents operation when open, and an emergency stop button for immediate shutdown during critical situations. These features minimize risk and ensure the safety of users during high-impact testing procedures.Q: What advantages does the digital automatic control offer for impact testing?

A: Digital automatic control allows for precise parameter adjustment, easy sample placement, quick response times, and error minimization. It streamlines workflow, reduces manual intervention, and improves repeatability of results, bringing efficiency and reliability to any impact resistance testing process.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email