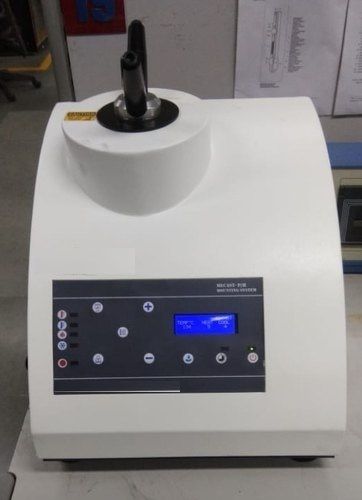

Automatic Mounting Press

140000 INR/Piece

Product Details:

- Response Time 2 seconds cycle time

- Port Size Standard 1/4 BSP

- Hardness Not Applicable (for mounting)

- Mounting Type Tabletop

- Frequency 50 Hz

- Gas Pressure Not Required (Electric Operation)

- Application Metallurgical Sample Preparation

- Click to view more

X

Automatic Mounting Press Price And Quantity

- 140000 INR/Piece

- 1 Piece

- Thermal cut-off, door safety interlock, excess pressure relief

- 530 x 410 x 430 mm

- Automatic water-cooled or air-cooled cycle

- Heat-resistant Bakelite or phenolic

- 1000 W

- Industrial standard blue/grey

- High-strength steel with non-stick coating

- 0200 bar (hydraulic)

- 25 minutes per cycle

Automatic Mounting Press Product Specifications

- Ambient, 1045C operating

- Metallographic Sample Mounting

- Max. 40 mm (specimen)

- Digital (LED/LCD)

- 0150 mm

- 220V AC

- 430 mm (with cover closed)

- Up to 2 samples / cycle

- Automatic operation, digital display, programmable cycles, feather touch control

- Automatic Mounting Press

- Adjustable, up to 180 mm/min

- 1050 mm diameter

- 0.1 mm

- Simple Keypad / Digital Display

- 0.01 mm

- 25 mm, 30 mm, and 40 mm diameter

- 1 or 2 per cycle

- 220V AC

- Up to 85% RH, non-condensing

- Feather Touch

- Automatic

- 1050 mm mounting diameter

- Metallurgical Sample Preparation

- 50 Kilograms (kg)

- 50 Hz

- Not Required (Electric Operation)

- Not Applicable (for mounting)

- Standard 1/4 BSP

- Tabletop

- 2 seconds cycle time

- Thermal cut-off, door safety interlock, excess pressure relief

- 530 x 410 x 430 mm

- Automatic water-cooled or air-cooled cycle

- Heat-resistant Bakelite or phenolic

- 1000 W

- Industrial standard blue/grey

- High-strength steel with non-stick coating

- 0200 bar (hydraulic)

- 25 minutes per cycle

Automatic Mounting Press Trade Information

- Cheque

- 1-2 Week

- Eastern Europe, Western Europe, Middle East, Central America, South America, Australia, Asia, North America, Africa

- All India

Product Description

AUTOMATIC SPECIMEN MOUNTING PRESS

This Machine is Automatic Mounting Press for metallographic specimen. It is suitable for all Thermosetting Materials, because of the cooling system. It can automatically finish with the heating temperature, the holding time and acting force. The operator can change 4 specification patterns according to the difficult specimens. It can make 2 specimens at one time.

SPECIFICATION:

- Pattern specimen : 25mm, 30mm, 40mm, 50mm

- Power: 220V 50Hz

- Maximum consumption: 1800W

- Pressure: 0~2Mpa

- Temperature: 0~300C

- Holding time: 0~99minutes

- Out line dimension: 615 x 510x 500mm

- Weight: 110Kg

- Cooling: Water cooling

Advanced Features for Reliable Metallography

This automatic mounting press incorporates a digital LED/LCD display, programmable operation cycles, and feather-touch controls, streamlining specimen mounting for metallography labs. Both water and air-cooling cycles ensure rapid turnaround, while the sturdy high-strength steel construction guarantees durability and easy maintenance. Designed for simplicity, operators benefit from adjustable cycle parameters and comprehensive safety systems for assured performance every time.

Precision and Efficiency in Sample Preparation

Achieve precise, repeatable results with an accuracy of 0.1 mm and a resolution of 0.01 mm. The hydraulic system enables a pressure range up to 200 bar for thorough specimen encapsulation, while the automatic cooling process accelerates cycle times. The machine mounts up to two samples simultaneously, increasing productivity without sacrificing quality or safety.

Safety and Ease of Use

The mounting press prioritizes user safety through thermal cut-off, door interlock, and excess pressure relief mechanisms. Intuitive feather touch controls and digital displays facilitate hassle-free operation, making it user-friendly even for less experienced personnel. This combination of safety, simplicity, and advanced technology ensures an optimal experience for all lab environments.

FAQs of Automatic Mounting Press:

Q: How does the automatic mounting press operate during the sample mounting process?

A: The press uses a programmable, fully automatic cycle featuring hydraulic pressure (up to 200 bar) and selectable cooling (water or air) to encapsulate specimens in heat-resistant Bakelite or phenolic molds. Controls are managed via a feather touch keypad and digital display for easy operation.Q: What types and sizes of specimens can be mounted using this machine?

A: It accommodates specimens with mounting diameters between 10 mm and 50 mm, specifically designed for 25 mm, 30 mm, and 40 mm diameters. The press can process one or two samples per cycle, making it ideal for various metallographic applications.Q: When should the mounting press be used in the sample preparation process?

A: The press is primarily used at the beginning of metallurgical sample preparation to encapsulate and protect samples, providing a stable medium for subsequent grinding, polishing, and analysis procedures.Q: Where is this automatic mounting press most beneficially employed?

A: It excels in metallurgical laboratories, research institutions, and industrial quality control labs where reliable and efficient sample mounting is essential for microscopic examination.Q: What safety measures are incorporated into the design of the press?

A: Safety features include an automatic thermal cut-off to prevent overheating, a door safety interlock to ensure the cover is securely shut before operation, and excess pressure relief to safeguard both users and the equipment.Q: What benefits does automatic operation provide compared to manual mounting presses?

A: Automatic operation ensures consistent cycle parameters, precise pressure and timing control, faster throughput (25 minutes per cycle), and reduced risk of operator error, resulting in superior and repeatable mounting results.Q: How is the cooling process handled, and why is it important?

A: The equipment offers both automatic water and air cooling cycles. Effective cooling ensures a rapid turnaround between cycles, preserves specimen integrity, and improves operator safety by minimizing handling of hot molds.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email