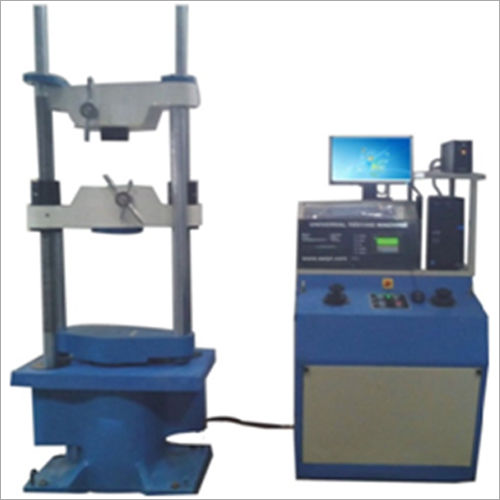

AMT 60SC Universal Testing Machine

3200000 INR/Unit

Product Details:

- Warranty 1 Year

- Voltage 220-440 Volt (v)

- Phase 3 Phase

- Color White And Blue

- Product Type AMT 60SC Universal Testing Machine

- Power Source Electric

- Frequency 50/60 Hertz (HZ)

- Click to view more

X

AMT 60SC Universal Testing Machine Price And Quantity

- 3200000 INR/Unit

- 1 Unit

AMT 60SC Universal Testing Machine Product Specifications

- AMT 60SC Universal Testing Machine

- Electric

- 1 Year

- Automatic

- 220-440 Volt (v)

- 50/60 Hertz (HZ)

- Mild Steel

- Industrial

- 3 Phase

- White And Blue

AMT 60SC Universal Testing Machine Trade Information

- 1 Unit Per Month

- 1-2 Week

Product Description

Description of Machine

- The machine should be for monotonic loadings to conduct the Tensile test, Compression test, Bend Test, Shear Test, etc. on different ferrous and non ferrous materials conforming to testing procedure laid down in IS/ASTM standards

- It should be based on Servo Hydraulic Closed Loop principle and fully computer controlled.

- It should be operated through Windows based software with ease of operation

- Machines should be automatic pace setting based on servo hydraulic closed loop principle

- In the series of machines the pace setting should be achieved through a combination of advanced electronic and hydraulic system

- Pacing speed should be programmed through the software/ touch panel in selectable control modes and controlled by servo/proportional valve through PID controller

- It should comply with various International and National standards

- The frame should have sufficient number of pillar to have better stability

- It should have easy cross head movement on the two pillars to adjust the gap with easy operation for specimen setting as per requirement

- It should be easily changeable hydraulically operated front Loading Grips for Tension test

- It should have controlling on both Load (kN/sec)/stress (N/mm/sec),

- Displacement (mm/sec) or Strain Control basis

- It should have facility to study Post failure behaviors of specimens

- It should have Auto release facility after specimen failure

- It should have 8 or 12 Additional input channels for external transducers

- It should have load measuring accuracy less than +0.5% of the measured value of Load in the Range from 2% -100% capacity

- It should have displacement measuring Accuracy less than +0.5% of the measured value of displacement

- It should have high speed Data acquisition and Statistical Analysis software

- It should have Online display of test data with real time plotting of Load-Time, Displacement-time, and Load-Displacement graphs, Stress-strain

- It should have Statistical analysis of the test results along with facility to export data to Excel

- It should have safety features like over travel limit for central cross head, over travel limit for ram and over loading of the system and overheating of oil should be provided as standard in the machine

- Hydraulic Pumping system should be based on Servo Hydraulic principle with servo/proportional valve to control motion of the cylinder/actuator

- It should be suitable for the supply of required flow and pressure for the movement of the actuator

- It should have an oil tank of adequate capacity, vane type pump powered by a three phase motor.

- All the electrical controls including the temperature controller should be fixed on one side of the tank.

- It should include all the accessories like pressure line filter, return line filter, oil level, relief valve, pressure gauge and air/water cooled heat exchanger

- Anti vibration mountings should be provided as standard along with the HPS.

- The machine may be operated with Power Supply- 440V, three phase

B PC system and Application Software for Controlling and Analysis

System shall be supplied with dedicated computer of following configuration or better for operation of the machine and analysis of test results

- Window based suitable software

- The software should have facility to hold machine load and restart loading or unloading for number of steps

- The software should have Independent Taring or Presetting of Load- Facility for auto-zeroing of deflection at preset load

- The software should have facility to save and retrieve test data along with order information about the specimen such as age, specimen no., size, dimensions etc. in user defined file/directory

- The software should have Calculation of various parameters such as load and elongation at yields, peak load and displacement at break, yield stress, Modulus of Elasticity, Ultimate tensile strength, Proof stress, compressive strength etc.

- The software should have facility to export data to Excel or PDF

- Desktop or laptop Computer with latest Processor or i7/12" generation

- 32" TFT Screen

- 1TB SSD

- 16 GB RAM extendable

- DVD, R/W drive

- Key Board

- Wireless Optical Mouse

- 6 USB Ports

- Laser Color Printer

- Multifunctional B/W printer

- 1000 VA UPS to operate the computer

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email