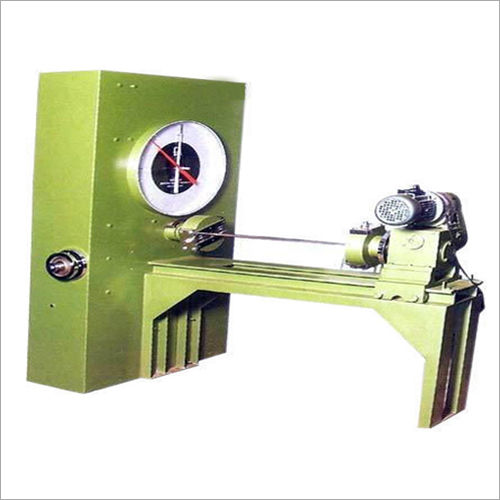

Torsion Testing Machine

50000.00 - 100000.00 INR/Piece

Product Details:

- Interface Type RS232 / USB (Optional)

- Automation Grade Semi-automatic

- Operating Voltage 220V Single phase AC

- Response Time Instantaneous

- Number of Specimens Single Specimen per Test

- Frequency 50 Hz

- Application Twisting/Torsional strength test of rods, wires, shafts, etc.

- Click to view more

X

Torsion Testing Machine Price And Quantity

- 50000.00 - 100000.00 INR/Piece

- 1 Piece

Torsion Testing Machine Product Specifications

- Instantaneous

- Twisting/Torsional strength test of rods, wires, shafts, etc.

- Up to 400 mm

- 50 Hz

- Single Specimen per Test

- Semi-automatic

- RS232 / USB (Optional)

- 220V Single phase AC

- Diameter up to 10 mm, Length up to 300 mm

- Up to 1000 Nm (depending on model)

- Table Top

- Up to 85% RH (Non-condensing)

- 0-2 RPM

- Full scale of each model

- Self-centering grips, digital display, protective cover, customizable jaws

- 400 mm (Between centers)

- Approx. 150 kg

- Ambient, 10C to 40C

- 220V AC, 50 Hz

- Variable (based on grips)

- Manual / Motorized

- Torsion Testing Machine

- Standard

- 0.01 Nm

- Digital and Analog (Dual Display, Model Dependent)

- 1% of indicated torque

- Material Testing, Quality Control, Research

- 20 Nm / 50 Nm / 100 Nm / 200 Nm / 500 Nm / 1000 Nm (Model Dependent)

Torsion Testing Machine Trade Information

- 100 Piece Per Week

- 5-7 Days

Product Description

We are instrumental in providing our clients a comprehensive range of Torsion Testing Machine. The offered machine is used to simulate real life service conditions and to check product quality for products. In order to maintain quality and avoid any flaw, this Torsion Testing Machine is stringently tested ion various quality parameters. This machine is useful for acquiring information like torsional shear stress, maximum torque and shear modulus.

Versatile Torsion Testing for Multiple Applications

This Torsion Testing Machine is engineered to assess the torsional or twisting strength of a variety of materials, including rods, wires, and shafts. Its adaptable test width and customizable jaws accommodate specimens up to 10 mm in diameter and 300 mm in length, making it suitable for a range of testing needs in materials research and industrial quality control.

Advanced Features for Precise and Safe Operation

With a high-torque AC motor, strain gauge-based torque sensor, and self-centering chucks, this machine delivers consistent, precise results. Safety mechanisms like the emergency stop and overload limiter protect both the operator and the equipment, ensuring reliable operation even in demanding environments.

User-Friendly Control and Data Management

Offering manual and motorized control modes, the machine allows users flexibility during testing. The dual digital/analog display provides instant readings, while data can be exported through RS232 or USB interfaces to a printer or computer. A supplied calibration certificate and comprehensive accessories package further enhance usability and compliance.

FAQs of Torsion Testing Machine:

Q: How does the Torsion Testing Machine ensure precise and repeatable results?

A: The machine utilizes a high-precision strain gauge torque sensor with an accuracy of 1% of indicated torque and a resolution of 0.01 Nm. Its self-centering jaws and stable, bi-directional drive motor contribute to accuracy and repeatability during the torsion testing process.Q: What specimens and capacity ranges can be tested with this machine?

A: Specimens up to 10 mm in diameter and 300 mm in length can be tested. The capacity of the machine is model-dependent, offering options of 20 Nm, 50 Nm, 100 Nm, 200 Nm, 500 Nm, or 1000 Nm to accommodate a wide spectrum of material strengths.Q: Where can the Torsion Testing Machine be used?

A: This machine is suitable for use in material testing labs, quality control departments, research centers, and manufacturing facilities. Its versatility and accuracy cater to a broad range of industries that require assessment of torsional properties.Q: What safety features are incorporated into this equipment?

A: The Torsion Testing Machine is equipped with an emergency stop button and an overload limiter to protect both the operator and the equipment during operation. Additionally, a protective cover and powder coating enhance user and equipment safety.Q: How can I collect and manage data from the test results?

A: Test data can be outputted to a printer or transferred to a computer via RS232 or optional USB interfaces. This ensures easy documentation, reporting, and further analysis of test outcomes.Q: What is the process for calibrating the machine?

A: Each machine is provided with a calibration certificate, assuring users of its accuracy. Regular calibration can be performed as needed using standard tools, and detailed procedures are available in the included user manual.Q: What are the main benefits of using this torsion testing machine?

A: Key benefits include high accuracy, versatile testing capacities, advanced safety features, user-friendly operation, dual data display, and compatibility with computer interfaces for streamlined data management.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email