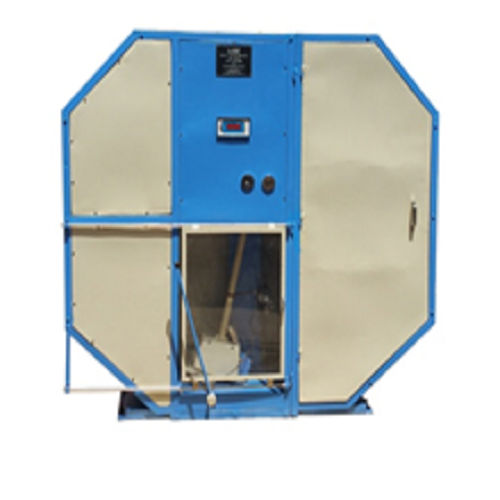

Fatigue Testing Machine

50000.00 - 100000.00 INR/Piece

Product Details:

- Frequency Up to 50 Hz

- Hardness Applicable for various hardness levels

- Interface Type Panel display

- Features Counter for Number of Reversals, Compact Design

- Max Height 450 mm

- Application Fatigue Strength Testing of Metals

- Resolution 0.01 Nm

- Click to view more

X

Fatigue Testing Machine Price And Quantity

- 1 Piece

- 50000.00 - 100000.00 INR/Piece

Fatigue Testing Machine Product Specifications

- Material Testing Laboratory, R&D

- Length: 100 mm, Diameter: 8 mm (standard)

- 175 kg (approx)

- Single specimen per test

- 2850 RPM

- 10 Nm 400 Nm

- 450 mm

- 0.01 Nm

- Rotating Beam Fatigue Tester

- Counter for Number of Reversals, Compact Design

- Fatigue Strength Testing of Metals

- Panel display

- Up to 50 Hz

- Applicable for various hardness levels

- Up to 30 mm

- Bench Top

- 0-400 Nm

- Digital Counter

- Standard for round or flat specimens

- 230 V AC, 50 Hz

- Up to 85% RH (non-condensing)

- Manual

- 230V AC

- 1%

- Ambient to 40C

- Instantaneous (digital display)

- 100 kg/cm

- Semi-automatic

Fatigue Testing Machine Trade Information

- 100 Piece Per Week

- 5-7 Days

Product Description

We are engaged in offering a wide range of precisely designed Fatigue Testing Machine, that tests by measuring the force put onto the sample over many, many cycles until the sample fails. In order to maintain quality and avoid any type of flaw, Fatigue Testing Machine is tested on diverse quality parameter before final delivery. This test is generally performed to measure the reduction in stiffness and strength of materials.

Precision in Fatigue Testing

This rotating beam fatigue tester is engineered for precise measurement, supporting a test range of 10 Nm to 400 Nm with 1% accuracy and 0.01 Nm resolution. The machine accommodates standard specimen sizes and ensures repeatable, reliable results, making it a trusted choice for material durability assessment.

Comprehensive Safety and User-Friendly Operation

The fatigue testing machine features a protective enclosure, overload protection, and a quick jaw clamping system to promote both user safety and operational efficiency. Its semi-automatic control mode, digital counter with preset capabilities, and compact benchtop design make it suitable for busy laboratory and R&D settings.

Built for Durability and Compliance

Constructed with a powder-coated, corrosion-resistant body, this machine withstands harsh lab conditions. It meets IS 5075 and ASTM E466 standards for fatigue testing, ensuring that results are recognized internationally. Its robust build supports long-term, intensive usage with minimal maintenance.

FAQ's of Fatigue Testing Machine:

Q: How does the fatigue testing machine measure fatigue strength in metals?

A: The fatigue testing machine employs a rotating beam method, applying repeated stress to a single metal specimen while recording the number of cycles until failure. The digital counter tracks revolutions up to 999999 reversals, providing accurate data on the specimen's fatigue life within the range of 10 Nm to 400 Nm.Q: What safety features are included in this fatigue testing machine?

A: Safety is ensured through a protective enclosure that shields the user from moving parts and debris. Overload protection prevents specimen or machine damage during tests, while the quick jaw-type clamping mechanism enhances secure mounting and easy specimen changes.Q: When should this machine be used in a laboratory setting?

A: This machine is ideal for material testing laboratories and R&D facilities whenever there is a need to evaluate the fatigue strength of metals. It is suitable for routine quality checks, research experiments, and development of new metal alloys that require verified endurance specifications.Q: Where can this machine be installed, and what are its space requirements?

A: The compact benchtop design allows the machine to be conveniently installed on laboratory workbenches. With dimensions of 750 mm x 350 mm x 450 mm (LxWxH), it fits well in standard laboratory environments without occupying excessive space.Q: What is the process for conducting a fatigue test using this machine?

A: To conduct a test, securely clamp a single metal specimen (standard: 100 mm x 8 mm) in the quick jaw system. Set the desired test parameters on the digital counter, start the drive motor at 2850 RPM, and monitor the machine as it applies cyclic stress until specimen failure or the preset reversal count is reached. Results are displayed instantly.Q: How does this machine benefit material testing laboratories?

A: The machine offers precise, rapid assessment of metal durability with minimal operator effort thanks to its semi-automatic operation, digital counter, and quick specimen handling. Its robust and standardized design minimizes downtime and ensures compliance with international testing standards, benefiting quality assurance and research outcomes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email