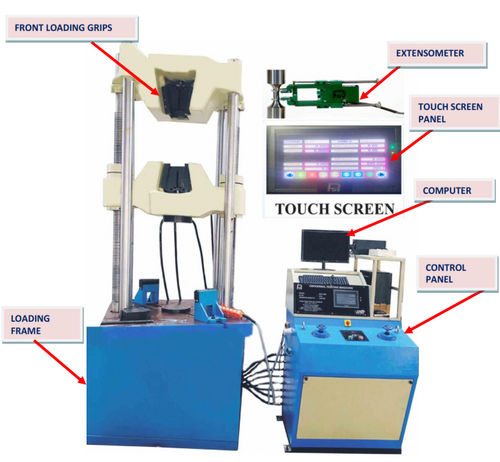

COMPUTERIZED SERVO CONTROLLED UNIVERSAL TESTING MACHINES CAPACITY-1000 KN

1250500 INR/Unit

Product Details:

- Application Tensile, Compression, Bending, Shear, and Flexural Testing

- Port Size Standard 16 mm

- Automation Grade Fully Automatic (Servo Controlled)

- Max Height 2200 mm

- Material Mild Steel

- Product Type UNIVERSAL TESTING MACHINES

- Interface Type USB, RS232 (optional)

- Click to view more

X

COMPUTERIZED SERVO CONTROLLED UNIVERSAL TESTING MACHINES CAPACITY-1000 KN Price And Quantity

- 1250500 INR/Unit

- 1250300.00 - 1250000.00 INR/Unit

- 1 Unit

- Four Column Rigid Frame

- Overload and Emergency Stop

- Hydraulic Wedge Action Grips

- Stepless via Servo Motor

- Strain Gauge Type

- Factory Calibrated - NABL Traceable Certificate Provided

- Computer Interface with Dedicated Software

- Digital Measure through Encoder

COMPUTERIZED SERVO CONTROLLED UNIVERSAL TESTING MACHINES CAPACITY-1000 KN Product Specifications

- Digital Display with PC Interface

- Room Temperature 10C-40C

- Three Phase, 415 V AC, 50 Hz

- 650 mm

- 1000 kN

- Free Standing

- 50 HRC

- 1% of indicated load

- Up to 40 mm diameter for round; up to 70 mm width for flat specimens

- Approx. 2000 kg

- 1 per test cycle

- 0.01 to 500 mm/min (variable, servo-controlled)

- Up to 85% RH

- Fully Automatic (Servo Controlled)

- Standard 16 mm

- Tensile, Compression, Bending, Shear, and Flexural Testing

- UNIVERSAL TESTING MACHINES

- USB, RS232 (optional)

- Mild Steel

- 2200 mm

- 0.01 kN

- Industrial

- Computerized Data Logging, Real-time Graph Display, Automatic Overload Protection

- 50 Hz

- Instantaneous

- 415 V AC

- 800 mm

- Blue

- Universal Testing Machine

- Computerized Servo Controlled

- 10 kN to 1000 kN

- Up to 1000 kN

- Four Column Rigid Frame

- Overload and Emergency Stop

- Hydraulic Wedge Action Grips

- Stepless via Servo Motor

- Strain Gauge Type

- Factory Calibrated - NABL Traceable Certificate Provided

- Computer Interface with Dedicated Software

- Digital Measure through Encoder

COMPUTERIZED SERVO CONTROLLED UNIVERSAL TESTING MACHINES CAPACITY-1000 KN Trade Information

- AS PER REQUIREMENT

- 1 Unit Per Month

- 60 Days

- WOODEN PACKING

- Australia, Central America, North America, South America, Western Europe, Middle East, Eastern Europe, Asia, Africa

- All India

- NABL CERTIFICATE

Product Description

COMPUTERIZED SERVO CONTROLLED FRONT LOADING HYDRULIC GRIP UNIVERSAL TESTING MACHINES CAPACITY-1000 KN MODEL AMT-100SC,1000 kN load capacity Servo Controlled Floor mounted Universal Testing Machine with double column load frame having facilities to carry out Tensile, compression, Bend/rebend, Wire mesh test, etcPrecision and Performance

Engineered with a strain gauge-type load cell and digital encoder extension measurement, this universal testing machine delivers 1% accuracy across a wide measuring range (10 kN to 1000 kN). Servo-controlled stepless speed adjustment (0.01500 mm/min) allows customized test settings, enhancing repeatability and versatile testing capabilities.

Advanced Data Acquisition and Control

Integration of computer interface and dedicated software ensures seamless data logging, real-time graph display, and robust analysis. Operators benefit from rapid response times and user-friendly operation via USB or optional RS232 interfaces, supported by a digital display for immediate feedback.

Safety and Reliability Assured

Safety mechanisms such as automatic overload protection and emergency stop buttons provide dependable operation. Factory calibration is NABL traceable, guaranteeing reliable test results and compliance with national standards, offering peace of mind to manufacturers, suppliers, and laboratories.

FAQs of COMPUTERIZED SERVO CONTROLLED UNIVERSAL TESTING MACHINES CAPACITY-1000 KN:

Q: How is data acquisition performed on this computerized universal testing machine?

A: Data acquisition is achieved using a dedicated computer interface and software, offering real-time graph display, digital recording, and instant response. The system supports USB and optional RS232 connectivity for easy export and analysis of test results.Q: What types of tests can this machine conduct?

A: This universal testing machine is capable of tensile, compression, bending, shear, and flexural tests. Its fully automatic, servo-controlled function and hydraulic wedge action grips enable precise testing of various specimen shapes, including round and flat samples.Q: When should the machine be recalibrated, and what certification does it provide?

A: The equipment is factory calibrated and issued with a NABL traceable certificate. Periodic recalibration is recommended based on usage intensity, typically annually, to maintain 1% load accuracy and compliance with industrial standards.Q: Where can this machine be installed, and what are the space requirements?

A: This free-standing machine requires three-phase power (415 V AC), with a maximum height of 2200 mm and weighs approximately 2000 kg. It should be installed in a spacious, ventilated industrial facility, suitable for high humidity (up to 85% RH) and temperatures between 10C40C.Q: How does the servo-controlled crosshead speed adjustment benefit testing?

A: The servo motor provides stepless crosshead speed adjustment from 0.01 to 500 mm/min, allowing users to set optimal speeds for different materials and test types. This results in more precise testing and improved repeatability.Q: What safety mechanisms are incorporated into the machine?

A: Safety features include overload protection and an emergency stop button to prevent accidental damage and ensure operator safety during high-capacity or hazardous testing scenarios.Q: What is the process for conducting a test with this machine?

A: To conduct a test, securely mount the specimen using hydraulic wedge action grips. Select the desired test parameters via the computer interface, initiate the servo motor for speed control, and monitor results on the digital display. After the cycle, data is automatically logged for analysis.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email