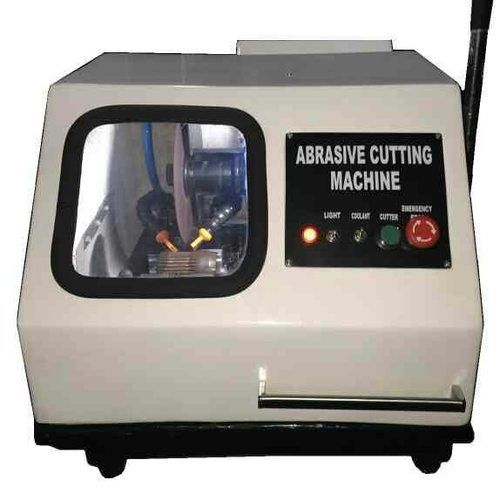

Automatic Abrasive Cutting Machine

450000 INR/Piece

Product Details:

- Measuring Range Cuts up to 75 mm cross-section

- Hardness Suitable for hard metals and alloys

- Resolution 0.1 mm

- Temperature 5C to 40C (Operating)

- Humidity 85% RH

- Response Time Immediate (on operation)

- Automation Grade Automatic

- Click to view more

X

Automatic Abrasive Cutting Machine Price And Quantity

- 1 Piece

- 450000 INR/Piece

- Adjustable Vice for various shapes

- 3 HP, Heavy-duty Induction Motor

- 700 x 600 x 400 mm

- <70 dB

- Yes, with anti-rust body finish

- Powder Coated Steel

- 250 mm diameter

- Integrated, recirculating with easy drain

- Yes, for lid and cutting area

- Internal LED illumination

Automatic Abrasive Cutting Machine Product Specifications

- 220V AC, 50Hz

- Safety cover, coolant circulation, low noise, overload protection

- 220V AC

- 2800 RPM

- Table Top

- Digital panel with status indicators

- Automatic

- 85% RH

- Sample preparation, sectioning

- 0.1 mm

- 5C to 40C (Operating)

- Suitable for hard metals and alloys

- Cuts up to 75 mm cross-section

- Cuts rods, plates, and irregular samples

- Automatic

- Immediate (on operation)

- 75 mm

- Push-button interface

- Manual and Programmable Options

- Up to 75 mm diameter

- Automatic Abrasive Cutting Machine

- Up to 75 mm diameter specimens

- High-precision, 0.1 mm

- 1 at a time

- Metallurgical sample sectioning, laboratory preparation

- 50 Hz

- Approx. 140 kg

- Standard 1/2 inch Water Inlet

- 100 mm (sample height with clamps)

- Adjustable Vice for various shapes

- 3 HP, Heavy-duty Induction Motor

- 700 x 600 x 400 mm

- <70 dB

- Yes, with anti-rust body finish

- Powder Coated Steel

- 250 mm diameter

- Integrated, recirculating with easy drain

- Yes, for lid and cutting area

- Internal LED illumination

Automatic Abrasive Cutting Machine Trade Information

- Cheque

- Western Europe, Australia, North America, South America, Eastern Europe, Central America, Africa, Middle East, Asia

- All India

Product Description

Abrasive cutter is rugged, sturdy and designed to cut Metallurgical Samples to optimal quality consistently and safely . Cutting Wheel spindle is connected with motor shaft by pulley and belt mechanism. The movement of cutting wheel towards the specimen is applied by handle fixed with motor base pivot spindle and the cutter unit is balanced by springs for smooth Chop Type/ Automatic movement. Corrosion resistant window. Cooling by two high flow water jets to provide optimum cooling. Large (25mm) drain, re-circulation coolant tank with 30-100LTR. Capacity Working on 440 volts, AC main supply with coolant tank of sufficient capacity.

Specifications:

- Heavy duty sectioning machine for large cross sections, irregular components, in short time.

- Cutting wheel swings also with the oscillation movement for faster large sectioning than the chop type.

- Heavy duty motor is provided 10/15 HP 3 phase.

- Machine is covered with powder coated sheets or stainless steel sheets.

- Specially designed heavy steel vice to hold any kind of piece.

- Absolute minimal deformation, cool & burn-free sample production.

- Large and effective coolant delivery with adjustable focused vains fitted on wheel guard.

- Coolant circulation system is provided with suitable filtering arrangement.

- Double light attachments system is provided for clean and accurate cutting of samples.

- Large viewing window to monitor the cutting operation.

Technical Data-

- Operation Manually/Automatic moving motor to cut the sample.

- Cutting Operation :- By manual/Automatic cutt-off wheel.

- Cutting Motor Power :- 10/15H.P,3 Phase.

- Coolant Motor Power :- Tullu Pump.

- Cutt-Off Wheel Speed :- 1440 RPM.

- Cutting Wheel :- 350 x 2.5 x 31.75

- Cutting Capacity :- Upto 150mm.

Precision Cutting for Laboratory Applications

Designed specifically for laboratory and metallurgical sample sectioning, this automatic abrasive cutting machine guarantees precise, clean cuts on a wide range of materials, including hard metals and alloys. With a measuring accuracy of 0.1 mm and programmable options for manual or automated control, it accommodates specimens up to 75 mm in diameter with ease and consistency, enhancing your workflow and reliability.

Safety and Convenience Features

Equipped with advanced safety interlocks for the lid and cutting area, low-noise operation, and overload protection, this machine prioritizes user safety without compromising performance. The built-in LED illumination enhances visibility during operation, while the integrated coolant system, equipped with a recirculating drain, ensures specimens remain cool and machine longevity is maximized.

Built for Heavy-Duty, Continuous Operation

Manufactured with a powder-coated, anti-rust steel body and a robust table-top design, the machine is both durable and easy to maintain. Its adjustable vice accommodates various sample shapes and sizes, allowing flexibility for different laboratory requirements. The digital control panel and immediate response time simplify user interface, making this equipment an essential tool for industry professionals.

FAQs of Automatic Abrasive Cutting Machine:

Q: How does the automatic abrasive cutting process work in this machine?

A: The machine uses a 250 mm abrasive cutting wheel powered by a 3 HP induction motor. Place your specimen in the adjustable vice, secure the safety cover, and select the desired settings via the push-button interface and digital panel. The automatic control mode initiates a precise cut, with programmable stroke options for varied sample requirements.Q: What types of samples can the machine cut, and what is its maximum capacity?

A: The machine is designed for cutting rods, plates, and irregularly shaped specimens made of hard metals or alloys. It can section samples up to 75 mm in diameter and a maximum height of 100 mm when clamped.Q: When should the integrated coolant system be used, and how does it benefit the cutting process?

A: The coolant system should always be utilized during operation. It recirculates coolant to keep the cutting area cool, minimizing specimen heat damage and prolonging both wheel and machine life. The easy-drain feature simplifies maintenance after cutting.Q: Where is this machine typically installed and operated?

A: This equipment is intended for use in laboratories or workshops, usually placed on a sturdy tabletop. Its compact (700 x 600 x 400 mm) and corrosion-resistant design ensures it fits well in various industrial and research environments.Q: What safety features are included in this model?

A: For safety, the machine features interlocks for both the lid and cutting area, preventing operation if covers are open, overload protection to safeguard the motor, and low noise (<70 dB) operation for operator comfort. Internal LED lighting further improves safe specimen handling.Q: How accurate are the cuts, and what is the measuring resolution?

A: The machine provides high-precision cutting with an accuracy of 0.1 mm and a measurement resolution of 0.1 mm, ensuring reliable sample sectioning for metallurgical analysis.Q: What benefits does the digital control panel offer for users?

A: The digital control panel displays operational status, cutting progress, and immediate response to user input via push-button controls, offering simple operation and clear visibility for efficient workflow management.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email